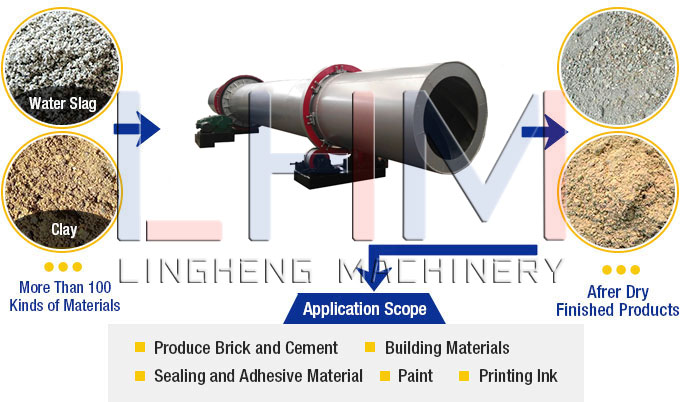

Introduction: Rotary Dryer Machine is also called rotary drying machine,which is especially widely used as mining equipment.Roller dryer is suitable for drying metallic and nonmetallic materials such as clay, coal slurry, sludge, gypsum, etc.

Rotary Dryer Machine is also called rotary drying machine,which is especially widely used as mining equipment.Roller dryer is suitable for drying metallic and nonmetallic materials such as clay, coal slurry, sludge, gypsum, etc. Rotary drum dryer also can be used for drying all kinds of mineral powder after ore dressing operation, such as iron powder, copper powder, manganese powder, tin powder, etc.

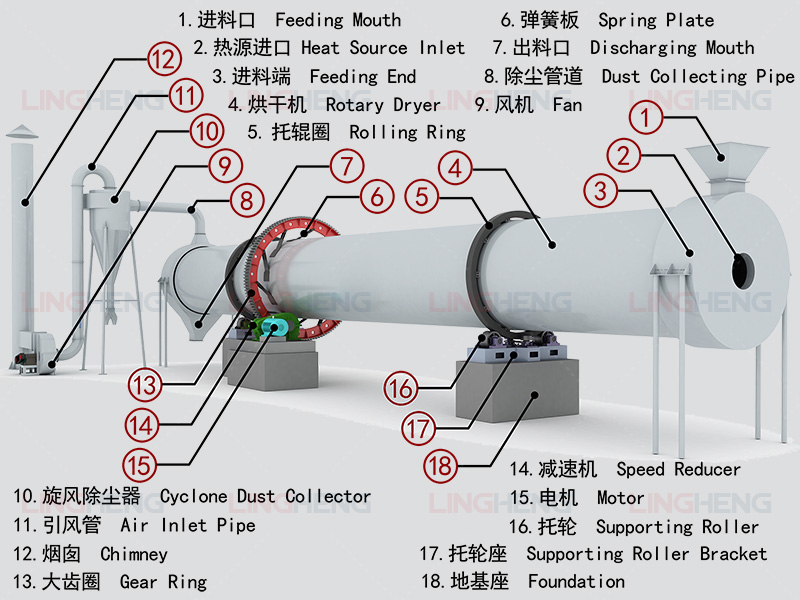

The rotary dryer, as a material heating and drying device, realizes drying process by making materials inside the coaxial rotary drum move back and forth between the inner and external wall driven by the spiral vane and interrupted spiral raising plate.

Rotary dryers or kiln dryers are mainly used to dry slag, clay and coal powder in the construction and metallurgy industries, and leaching residue of the metal processing industry.

Working Principle of Rotary drying Machine

Rotary dryer is mainly composed of rotary part, lifting board, transmission part, supporting part and seal ring. Since the dryer machine is obliquely installed, the materials flow to the lower end of the machine under the gravity and the rotation of the machine, and on the other hand, the materials are repeatedly lifted by the lifting board to the higher end and then spread down constantly, so that the materials will form a even curtain inside the cylinder and conduct heat exchange with the hot air inside the cylinder. Since the materials constantly spread and the water contained in them will be dried, thus achieving the aim of drying.

Features of Our Rotary Drying Machine

1. Rotary drying machine manufactured by Ling Heng Machinery adopts new multi-stage combined feeding device, which can overcome the phenomenon of "wind tunnel" compared to traditional dryer, so as to improve the utilization of heat energy and reduce the consumption of coal.

2. The rotary dryers can be equipped with various combustion furnaces, such as: high-temperature fluidized bed, grinding combustion furnace and artificial coal stove.

3. Gear isreplaceable, which helps to save cost and reduce maintenance time.

4. The centralized control system can realize automation management for large enterprises.

Technology Data of Rotary Drying Machine

|

Spec./m (Dia.* Length) |

Shell Cubage (m³) |

Capacity (t/h) |

Installation Obliquity (%) |

Highest Inlet Air Temperature (oC) |

Main Motor (kw) |

Weight (t) |

| Ø0.8*8.0 | 5.7 | 0.8~2.0 | 3~5 | 700~800 | 4 | 3.6 |

| Ø1.2*8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Ø1.2*10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Ø1.5*12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Ø1.5*14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Ø1.5*15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Ø1.8*12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Ø1.8*14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Ø2.2*12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Ø2.2*14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Ø2.2*16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Ø2.4*14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Ø2.4*18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Ø2.4*20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Ø2.4*22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Ø2.6*24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Ø3.0*20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Ø3.0*25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Ø3.2*25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Ø3.6*28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!